Technics SL-1200 Ground Wire

June 3, 2024

I’ve done a few of these over the years, but this is the first time I’ve had one where the customer tried to DIY before bringing it to me. Not too shabby for an amateur, but what they did defeats the whole purpose of the extra ground wire, which is to provide an isolated ground for the tone arm.

From the factory, the tone arm is grounded to the chassis, and the cartridge wires are not. So what you don’t want to do is solder the cartridge wires to the chassis ground.

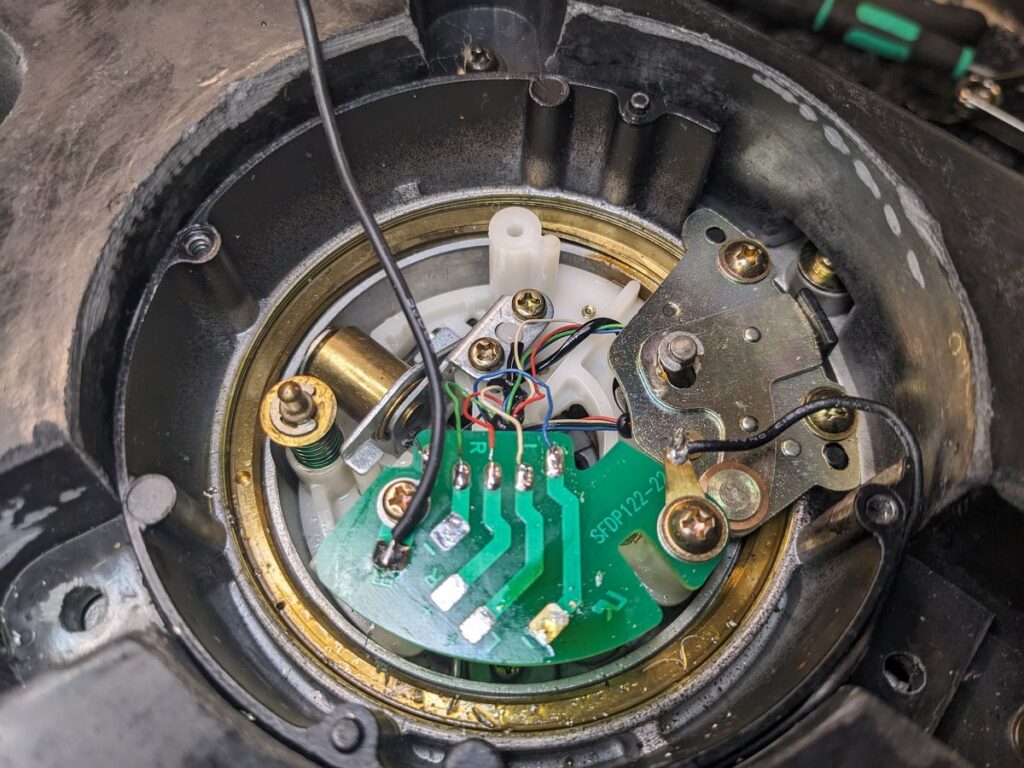

So my first task was to remove the wires installed by the customer and clean up the circuit board, then install the extra ground wire without connecting it to the cartridge wires.

Next, “dress” the ends of the patch cord and solder to the clean interconnect board. “Dressing” is the process of cutting, stripping, twisting, and tinning the wire ends so they fit perfectly and solder securely.

I know, and you should know, that if you use the overly thick patch cords, the factory strain relief clamp is not going back on again. To keep the wire connections secure, I epoxied the wires to the circuit board. Believe me when I tell you, there is no advantage to the extra thickness. In this case, it was mostly extra rubber, but extra wire doesn’t make much different at all in a low frequency, low current situation.

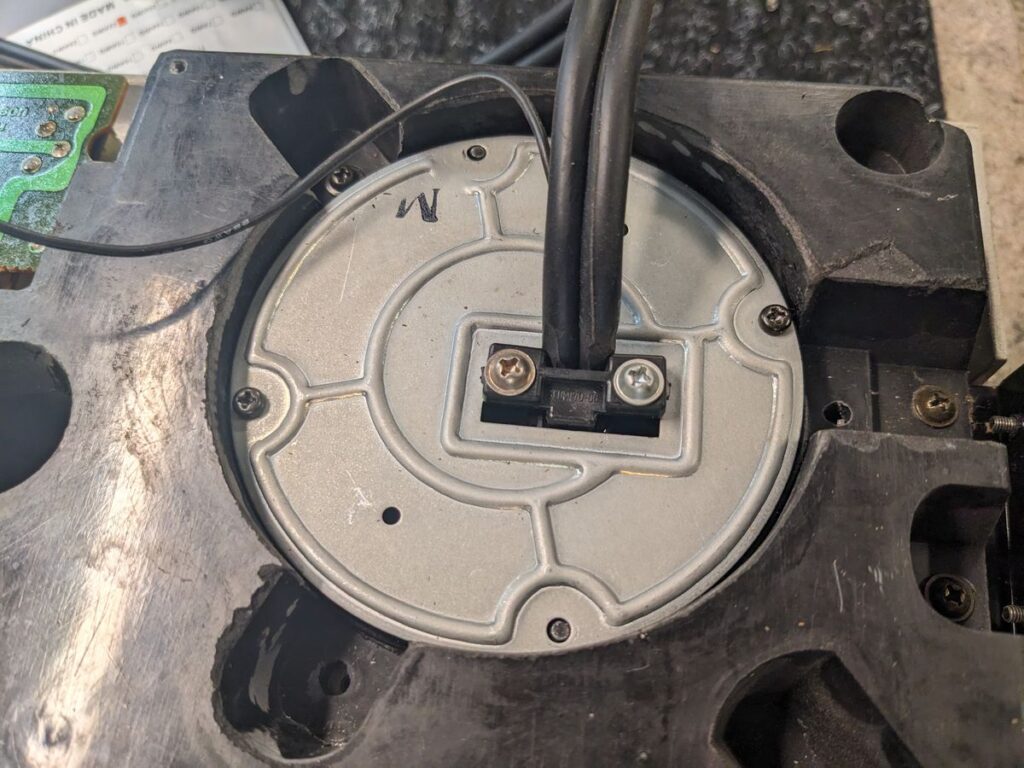

Next the original cover is reinstalled, taking care not to yank on the wires, which in turn would yank on the epoxy seal, possibly breaking it (and other things!).

And last, I reinstall half of the original strain relief clamp. The oversize patch cord is firmly clamped in place.